INP-WealthPk

Faiza Tehseen

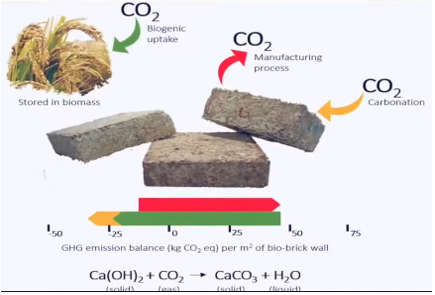

Production of bio-bricks at the commercial level by using agricultural waste and recyclable material can help Pakistan minimize CO₂ emissions and pollution, opined Muhammad Naveed, Project Engineer at the Sindh People’s Housing for Flood Affectees (SPHF), while talking to WealthPK. “Unlike conventional kiln-fired bricks, which cause environmental pollution, bio-bricks are a zero-carbon product with low energy consumption (they are processed at room temperature),” he said.

Bio-bricks also offer significant economic benefits, including decreased construction cost and increased job opportunities. Unlike the linear economy based on ‘take, make, and dispose’ practice, the circular economy is based on the ‘make, use, and recycle’ model. Bio-brick production is a true picture of the circular economy model.

“A variety of agricultural waste and natural materials can be used to produce bio-bricks. They may include rice husk, hemp shiv, wheat straw, sugarcane bagasse, loofah, and charcoal. The recycled materials include soil, cement, gypsum, fly ash, recycled concrete aggregates, and even bacteria mixed with urea and calcium sources like urine, which reduce resource consumption and waste,” he said.

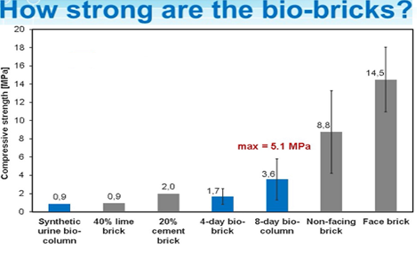

He said soil and cement are often combined with other materials to create a binding matrix for bio-bricks. Gypsum can also be used as a binder, especially when combined with other agricultural wastes. Bacteria-manufactured bricks reduce carbon emissions by nearly 800 million tonnes per year.

Naveed said, “A specific bacterium is used to grow bio-bricks. These bacteria produce urease, an enzyme that breaks down urea (in urine or other sources) into carbonate ions. These ions then react with calcium, typically from calcium hydroxide, to form calcium carbonate, which acts as a natural cement binder for loose sand or other materials together.”

Naveed said Pakistan needs to meet multiple sustainability goals to address the impacts of climate change and environmental issues. Bio-bricks and in-kind practices help create paradigm shifts through education. So, there is a need to manufacture them locally.

“Resource recovery is important for a sustainable future and environmental safety. By establishing bio-brick manufacturing units, Pakistan will have more employment and business opportunities. Bio-bricks self-repair automatically, as microorganisms precipitate minerals,” Dr. Tahira, Principal Scientist at the National Agricultural Research Centre (NARC), told WealthPK.

“Introducing bio-bricks in local constructions will not only reduce the cost of construction material, but a good number of waste materials will also be recycled and dumped properly. So, it is important to popularize the use of such materials,” she said.

Credit: INP-WealthPk