INP-WealthPk

Azeem Ahmed Khan

While maize is widely cultivated across the country, with Punjab and Khyber Pakhtunkhwa leading production, its uses remain largely limited to food, fodder, and animal feed. Experts believe that expanding its role to value-added products could enhance food security, lift rural incomes, and energize the agro-industrial sector, WealthPK reports.

“Globally, maize is processed into a wide range of value-added products, but in Pakistan, only a few such products are available,” Aamar Shehzad, Scientific Officer at the Maize Research Station, Ayub Agricultural Research Institute, Faisalabad, told WealthPK.

Transforming maize from a subsistence crop into a versatile raw material for feed, fuel, food, and industrial products can significantly increase farmer incomes and support agro-industrial development, he said.

Aamar said maize ranks as the third most important cereal crop in Pakistan, next to wheat and rice, with around 65% of production used as poultry and animal feed. Converting raw maize into processed feed, such as silage, can significantly increase its market value and improve returns for farmers, he added.

“Maize silage is an efficient, high-yield fodder, and selling silage instead of raw grain allows farmers to earn more per acre,” he explained. Investments in modern feed mills and improved supply chains could further enhance livestock productivity,” he said.

Aamar highlighted several industrial applications of maize, including its use in the production of ethanol, an essential component in pharmaceuticals and biofuels, as well as industrial starch, oil and glucose, which serve as key ingredients in the paper, textile, and food processing industries. Additionally, he said, maize stubble can be utilized as fuel for boilers and is often chopped and incorporated into the soil to enhance fertility levels.

Maize flour, he noted, is particularly beneficial for people with celiac disease or gluten intolerance and is a common ingredient in multi-grain flours. Maize flour also has a sweet taste, making it suitable for food and beverage production, fermentation, and pharmaceuticals, he added.

Corn oil derived from maize offers significant nutritional benefits, while its by-product corn cake serves as a valuable animal feed, he said. Maize is also used in biodiesel production in developed countries, providing a cleaner alternative to fossil fuels, he added.

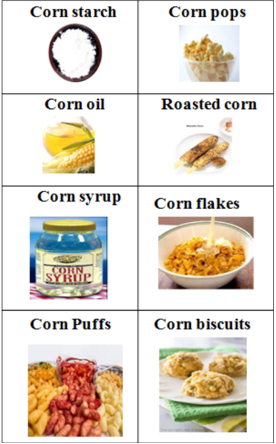

Processed maize products such as corn flakes, popcorn, corn oil, corn flour, and tortillas are gaining popularity in Pakistan, especially in urban markets.

“These products command significantly higher prices than raw maize, underscoring the crop’s untapped potential in value addition,” Aamar said.

The country’s growing urban population and changing dietary habits have increased the demand for ready-to-eat maize-based foods, he noted. Diversifying maize cultivation, he added, could open new export opportunities for products like frozen sweet corn and popcorn.

At the Maize and Millets Research Institute, Sahiwal, new sweet corn and popcorn varieties have been developed for affordable cultivation and consumption, he pointed out. Sweet corn is sweeter than regular varieties, and ideal for steaming, boiling, or canning.

“Pakistan’s popcorn variety is sweeter than those commonly available and is a healthier snack option, especially for schoolchildren when mixed with jaggery – a much healthier alternative to unhealthy snacks like crisps and sweets,” he stressed.

Nutritionally, 100 grams of maize grain contain 60-65% carbohydrates, 8-10% protein, 2-3% oil, as well as vitamins B and C, antioxidants, and essential minerals like iron and potassium.

Despite this potential, several barriers hinder maize value addition in Pakistan. A key challenge is the limited awareness among smallholder farmers, many of whom are unfamiliar with the economic benefits of processing maize, he said.

Aamar noted that many rural areas lack access to basic maize drying, storage, and processing facilities, which prevents farmers from fully participating in more profitable value chains.

“If modern drying facilities are made available at the farmer level, we will be able to export maize grain for both food and feed, leading to better profits. Clean and efficient drying also helps prevent aflatoxin contamination, a major barrier to exporting high-quality maize,” he said.

Credit: INP-WealthPk