INP-WealthPk

Ahmed Khan Malik

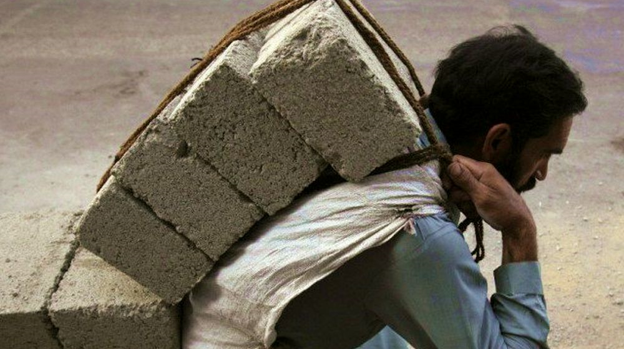

Labour productivity in Sindh’s industrial sector remains very low stemming mainly from outdated machinery, lack of innovation and unskilled workforce, making it difficult for industries to compete in the global market.

Productivity simply means how much output a worker can produce in a given time. It is a measure of efficiency and plays a big role in deciding whether industries can compete in today’s tough global markets.

Unfortunately, workers in Sindh are producing less. This weak performance is holding back not only industrial growth but also job opportunities and incomes for thousands of families.

Experts and industrialists have pointed out several reasons behind low labour productivity in Sindh’s industries

“Many factories still use outdated machines and rely heavily on manual labour. We are working on machines that are 30 years old,” Asad Shah, a labour welfare leader, told WealthPk. “They break down often, and when that happens, production stops for hours.”

He said technical education and training in Sindh has not kept pace with modern needs. “Employers often complain that graduates don’t have the skills they need,” he said, adding that without proper training, workers cannot adapt to new technologies.”

Asad noted that productivity is not only about workers. “It also depends on how industries are managed. Unfortunately, weak planning, old-fashioned practices, and reluctance to adopt new ideas are common in many factories. Our competitors use modern systems, but here many managers still run things the old way,” he said.

Frequent electric cuts, gas shortages, and weak transport systems interrupt production lines. Even when workers are ready, they cannot deliver if the machines do not run or goods cannot reach markets on time, Asad explained.

The labour welfare leader said poor working conditions, low wages, and lack of job security also play a role. “Labourers work 10 to 12 hours a day but still struggle to pay for basic needs.”

Low productivity has serious consequences. For one, Sindh’s industries find it harder to compete internationally. Pakistan’s exports in textiles and other products already face stiff competition, and inefficiency makes matters worse, he noted.

“When orders come from abroad, buyers look at speed and quality,” said Muneeb Saeed, a representative of the Karachi Chamber of Commerce and Industry. “If we cannot deliver on time, those orders go to Bangladesh or Vietnam.”

At the same time, when output is low, wages remain low as well. Workers continue to struggle with rising living costs while industries complain of low profits, he told WealthPK.

“Another impact is on investment. Local and foreign investors prefer to put money where productivity and returns are higher. If Sindh’s industries fail to improve, new investment may shift to other countries, leaving the province behind,” Saeed cautioned.

He said that Sindh’s industries stand at a crossroads. “On one hand, they face declining competitiveness, low wages, and energy shortages. On the other, they have the chance to modernise, train their workforce, and grow stronger.”

“If we invest in our workers and technology, productivity will rise, exports will grow, and everyone will benefit,” he said.

“It’s not just about industries — it’s about the future of Sindh’s economy.”

Credit: INP-WealthPk